Attention

Close

STEEL CONSTRUCTION | Structural Steel

Steel is the most versatile and important metal alloy.

Steel is produced in a wide variety of types and shapes, each one is capable of efficiently satifying one or more applications. Such variety results from the continuous need to adequate the product to specific application requirements that appear in the market, either due to the need to control chemical compositions or to assure specific proprieties, which includes the final shape (plates, profiles, pipes, bars, etc.).

There are more than 3,500 different types of steel and around 75% of them were developed in the last 20 years. This shows a huge evolution in the sector.

Carbon steel have in its composition only limited amounts of chemical elements such as carbon, silicon, manganese, sulfur and phosphorus. Other chemical elements exist only in residual amounts.

The amount of carbon in the steel defines its classification. Low-carbon steels have a maximum of 0.3% of said element and show great ductility. They are more appropriate for mechanic and welding works, not being hardenable, and are used in the construction of buildings, bridges, ships, vehicles, among other uses. Medium-carbon steel has 0.3 to 0.6% of carbon content and are used in gears, connecting rods and other mechanical components. This steel, if hardened and tempered, can reach good tenacity and resistance. High carbon steel has more than 0.6 of carbon content and has high durability and resistance after tempered. They are commonly used in rails, springs, gears, agricultural components subject to wearing, small tools, etc.

In civil construction, the highest interest falls upon the so called structural steels of mid and high-mechanic strength, a term used to designate all steels that due to their resistance, ductility and other properties are appropriate to be used in construction elements subject to loading. The main requirements for the steels intended to structural applications are: high flowing stress, high tenacity, good weldability, microstructural homogeneity, susceptibility to flame cutting without hardening and good workability in operations such as cutting, drilling and bending, without causing fissures or other defects.

Structural steels may be sorted in three main groups according to the minimum specified flowing stress.

| TIPO | LIMITE DE ESCOAMENTO MÍNIMO, MPa |

|---|---|

| Aço carbono de média resistência | 195 a 259 |

| Aço de alta resistência e baixa liga | 290 a 345 |

| Aços ligados tratados termicamente | 630 a 700 |

Among the currently existing structural steels, the most used and known type is the ASTM A36, which is rated as a medium-mechanical strength carbon steel. However, the modern trend of using ever-growing structures has led engineers, designers and builders to use steels with increased resistance, the so-called high-strength and low-alloy steels, with the purpose of avoiding the erection of heavier structures.

High-strength and low-alloy steels are used whenever there is the need to:

- Increase the mechanical resistance in order to allow an addition of structural unit load or to allow a proportional section decrease, that is, the use of lighter sections;

- Improve the resistance against atmospheric corrosion;

- Improve resistance to impact and fatigue limit;

- Increase the relationship between flowing limit and traction-resistance limit without significant loss of ductility.

Among the steels belonging to this category, the ones in the spotlight are the high-strength and low-alloy steels resistant to atmospheric corrosion. This steel was introduced in the American market in 1932 to be specifically applied to the manufacturing of cargo wagons. From its launching to the current days, other steels with similar behaviors were developed, which constitute the family of steels known as patinable, which would soon be ruled by several standards, such as the Brazilian NBR 5008, 5920, 5921 and 7007 and the American ASTM A242, A588 and A709 with the purpose of establishing limits to their chemical compositions and mechanical properties. Those steels have been used in the whole world to build bridges, viaducts, silos, power transmission towers, etc. Its major advantage, in addition to dismiss painting in certain environments, is having a mechanical strength higher than carbon steels. In extremely aggressive environments, such as regions with high levels of sulfur dioxide pollution or those near the shore, painting grants them a performance far superior than carbon steel.

What made a new carbon steel-based product unique, in terms of corrosion resistance, was the fact that under certain exposure environmental conditions, it could develop on its surface an adherent and protective oxide film, called patina, which acts by reducing the attack speed of corrosive agents found in the environment.

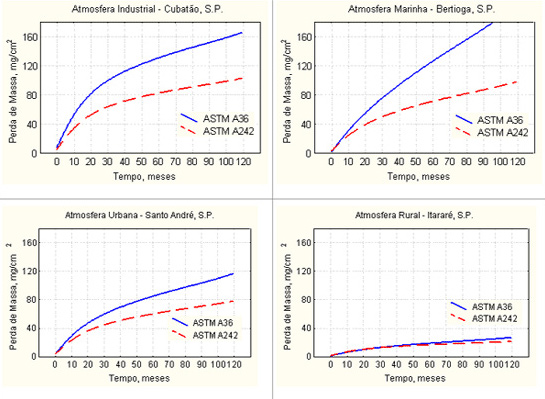

Figura 1. Resistência à corrosão de um aço patinável (ASTM A242) e de um aço carbono comum (ASTM A36) expostos às atmosferas industriais (Cubatão, S.P.), marinha (Bertioga, S.P.), urbana (Santo André, S.P.) e rural (Itararé, S.P.). A medida é feita em termos da perda de massa metálica em função do tempo de exposição em meses. Fonte: Fabio Domingos Pannoni, M.Sc., Ph.D.

Formation of patina can occur following three factors. The first one is related to the chemical composition of the steel itself. Main alloy elements that contribute to increased resistance against atmospheric corrosion (thus favoring the formation of patina) are copper and phosphorus. Chromium, nickel and silicon also exert secondary effects. However, it is worth emphasizing that phosphorus must be kept as low as possible (less than 0.1%) as it may compromise certain mechanical properties of the steel, as well as its weldability.

Secondly, there are environmental factors, such as the presence of sulfur dioxide and sodium chloride in the atmosphere, temperature, wind strength (direction, speed and frequency), wetting/drying cycles, etc. Therefore, while the presence of sulfur dioxide, up to certain limits, favors the development of patina, the sodium chloride suspended in maritime atmospheres compromises its protective properties. It is not recommended to use unprotected patinable steel inside industrial environments where the concentration of atmospheric sulfur dioxide is above 168mgSO2/m2.dia (United States and United Kingdom) and inside maritime atmospheres where the deposition rate of chlorides exceeds 50mg/m2.dia (United States) or 10 mg/m2.dia (United Kingdom).

Finally, there are factors associated with the geometry of the component, which explains why different structures of the same steel placed next to each other can suffer different attack levels. This phenomenon is caused by the influence of opened/closed sections, correct draining of rainwater and other factors directly affecting wetting and drying cycles. Therefore, for example, under continuous wetting conditions determined by poor drying, the formation of patina is severely compromised. In most of such situations, the corrosion speed of patinable steel is similar to the one of carbon steel. Examples include patinable steels immersed in water, buried in the ground or covered by vegetation.

High-strength and low-alloy steels resistant against corrosion are produced in Brazil by Several Steelmakers.

Tabela 1: Comparativo de composição química e propriedades mecânicas de aços ASTM.

Click here and see the table (*.pdf).

| ELEMENTO QUÍMICO | ASTM A36 (PERFIS) |

ASTM A572 (GRAU 50) |

ASTM A588 (GRAU B) |

ASTM A242 (CHAPAS) |

|---|---|---|---|---|

| % C máx. | 0,26 | 0,23 | 0,20 | 0,15 |

| % Mn | ... (1) | 1,35 máx. | 0,75-1,35 | 1,00 máx. |

| % P máx. | 0,04 | 0,04 | 0,04 | 0,15 |

| % S máx. | 0,05 | 0,05 | 0,05 | 0,05 |

| % Si | 0,40 | 0,40 máx.3 | 0,15-0,50 | ... |

| % Ni | ... | ... | 0,50 máx. | ... |

| % Cr | ... | ... | 0,40-0,70 | ... |

| % Mo | ... | ... | ... | ... |

| % Cu | 0,202 | ... | 0,20-0,40 | 0,20 mín. |

| % V | ... | ... | 0,01-0,10 | ... |

| (% Nb + %V) | ... | 0,02-0,15 | ... | ... |

| Limite de escoamento (MPa) | 250 mín. | 345 mín. | 345 mín. | 345 mín. |

| Limite de resistência (MPa) | 400-550 | 450 mín. | 485 mín. | 480 mín. |

| Alongamento Após ruptura, % (lo = 200mm) | 20 mín. | 18 mín. | 18 mín. | 18 mín. |

(1): Para perfis de peso superior a 634 kg/m, o teor de manganês deve estar situado entre 0,85 e 1,35% e o teor de silício entre 0,15 e 0,40%.

(2): Mínimo quando o cobre for especificado.

(3): Para perfis de até 634 kg/m.

(4): Espessuras entre 20 mm e abaixo.

Tabela 2: Os aços patináveis produzidos no Brasil.

Click here and see the table (*.pdf).

| EMPRESA | AÇO | WEBSITE |

|---|---|---|

| ArcelorMittal

Aços Longos |

ASTM A588 | www.arcelormittal.com.br |

| ArcelorMittal Tubarão |

CST COR 400 e CST COR 500 | www.arcelormittal.com/br/tubarao |

| Gerdau | ASTM A588, AÇOCOR 500 | www.gerdau.com.br |

| USIMINAS | USI-SAC-300, USI-SAC-350, USI-FIRE-350, ASTM A242, ASTM A588 | www.usiminas.com |

| V&M do Brasil SA | VMB 250 COR, VMB 300 COR, VMB 350 COR | www.vmtubes.com.br |

Tabela 3: Similaridade entre Normas de Aços estruturais para a Construção Civil.

Click here and see the table (*.pdf).

| NORMAS | MARCAS |

||||

|---|---|---|---|---|---|

| ASTM | EN | JIS | NBR | MERCOSUL | |

ASTM A36 |

EN 10025-2 S235JR EN 10025-2 S235J0 EN 10025-2 S275JR EN 10025-2 S275J0 |

JIS G3101 SS400 | ABNT NBR 6650 CF26 ABNT NBR 6648 CG26 ABNT NBR 7007 MR250 |

NM02 131 ED24 | VMB 250 |

| ASTM A 572 GR 42 ASTM A 1011 SS Grau 45 Tipo 1 ASTM A 1018 HSLA Grau 45 Classe 1 |

EN 10025 S275JR EN 10025 S275J0 |

... | ... | ... | CST CIVIL 300 USI CIVIL 300 VMB 300 |

| ASTM A 572 Grau 50 ASTM A 1018 HSLAS Grau 50 Classe 1 ASTM A 1011 HSLAS Grau 50 Classe 1 ASTM A 709 Grau 50 ASTM A 992 |

EN 10025 S355JR EN 10025 S355J0 |

JIS G3101 SS490 | ABNT NBR 5000 Grau 35 ABNT NBR 5004 Grau Q35 ABNT NBR 7007 AR350 |

NM02 102 MCF345 NM02 101 MCG360 |

CST CIVIL 350 USI CIVIL 350 VMB 350 |

| ASTM A 572 Grau 60 ASTM A 1018 HSLAS Grau 60 Classe 1 ASTM A 1011 HSLAS Grau 60 Classe 1 |

EN 10025 S450J0 | JIS G3101 SS540 | ABNT NBR 7007 AR415 | ... | ... |

| ... | EN 10155 S235J0 | JIS G3114 SMA400 | ABNT NBR 5921 CFR400 ABNT NBR 5008 CGR400 |

NM02 103 GR400 | VMB 250 COR |

| ASTM A 709 Grau 50W | EN 10025 S355J0W EN 10025 S355J2W |

... | ABNT NBR 5921 CFR400 ABNT NBR 5008 CGR400 |

NM02 103 GR400 | CST COR 400 USI SAC 300 (Antigo USI-SAC 41E ou USI-SAC 41MG) VMB 300 COR |

| ASTM A 242 ASTM A588 Grau 50 ASTM A606 Tipo 4 ASTM A 709 Grau 50 W |

EN 10025 S355J0W EN 10025 S355J2W EN 10155 S355J0W |

JIS G3114 SMA490 | ABNT NBR 5921 CFR500 ABNT NBR 5008 CGR500 ABNT NBR 5920 CFR500 ABNT NBR 7007 AR350 COR |

NM02 103 GR500 | CST COR 500 GERDAU AÇOCOR 500 USI-SAC 350 (Antigo USI-SAC 50) VMB 350 COR |

| ASTM A709 Grau HPS 70W | ... | JIS G3114 SMA570 | ... | ... | ... |

NOTAS:

Para qualidades de aço diferente das apresentadas, consultar as empresas produtoras.

(*) As similaridades das normas não implicam em igualdade das mesmas.

Data da última atualização: 12/02/2014

Click here and see the table (*.pdf).